Nkwakọ ngwaahịa dị elu bụ otu n'ime nkọwa teknụzụ nke oge 'Karịrị Moore'.Dị ka ibe ibe na-esiwanye ike ma dị oke ọnụ ka ọ dị ntakịrị na nhazi usoro ọ bụla, ndị injinia na-etinye ọtụtụ ibe n'ime ngwugwu dị elu nke mere na ha agaghịzi agbasi mbọ ike ibelata ha.Edemede a na-enye okwu mmalite dị mkpirikpi nke iri n'ime okwu ndị a na-ejikarị na teknụzụ nkwakọ ngwaahịa dị elu.

2.5D ngwugwu

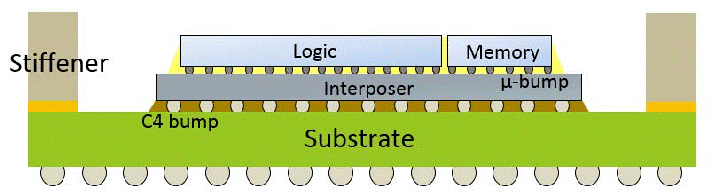

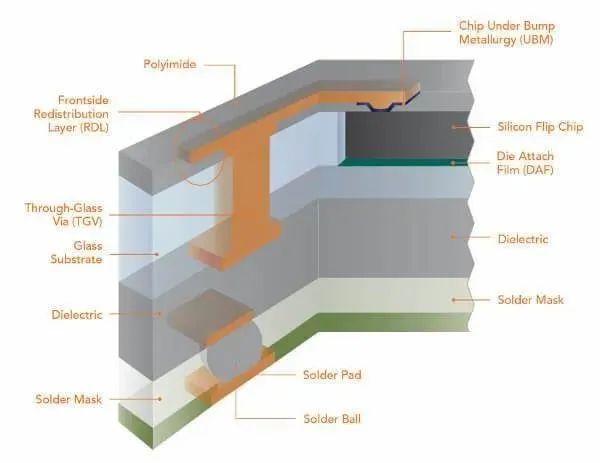

Ihe ngwugwu 2.5D bụ ọganihu nke teknụzụ nkwakọ ngwaahịa 2D IC ọdịnala, na-enye ohere maka ahịrị dị mma na iji oghere.N'ime ngwugwu 2.5D, a na-akwakọba ndị nwụrụ anwụ ma ọ bụ tinye n'akụkụ n'akụkụ n'elu oyi akwa interposer nwere silicon site na vias (TSVs).Isi, ma ọ bụ interposer oyi akwa, na-enye njikọ n'etiti ibe.

A na-ejikarị ngwugwu 2.5D maka ASIC dị elu, FPGA, GPU na cubes ebe nchekwa.2008 hụrụ Xilinx kewara nnukwu FPGA ya n'ime obere ibe anọ nwere mkpụrụ dị elu wee jikọọ ndị a na oyi akwa silicon interposer.A mụrụ ngwugwu 2.5D wee mesịa bụrụ nke a na-ejikarị eme ihe maka ntinye ihe nrụpụta bandwidth dị elu (HBM).

Eserese nke ngwugwu 2.5D

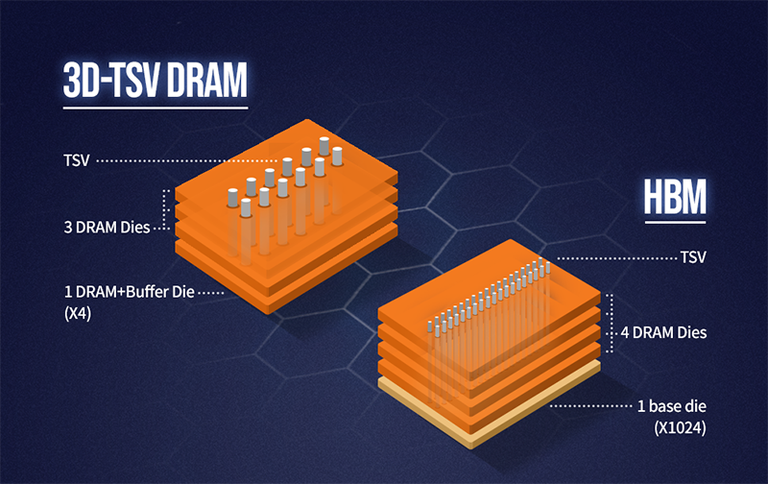

Nkwakọ ngwaahịa 3D

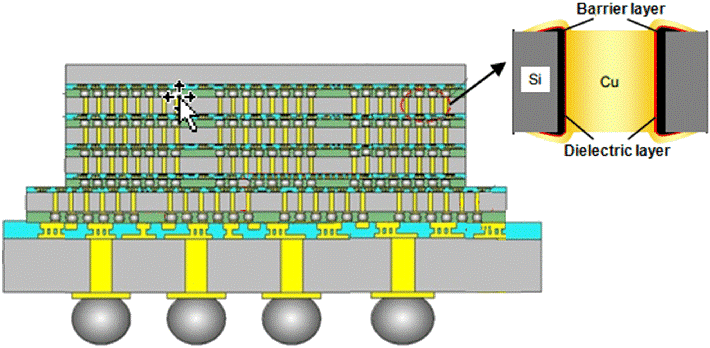

N'ime ngwugwu 3D IC, a na-ejikọta ọnụ ọgụgụ ezi uche ma ọ bụ jiri nchekwa nchekwa, na-ewepụ mkpa ọ dị iji wuo nnukwu Sistemu-na-Chips (SoCs).A na-ejikọta ndị nwụrụ anwụ na ibe ha site na oyi akwa interposer na-arụ ọrụ, ebe ngwugwu 2.5D IC na-eji bumps conductive ma ọ bụ TSV iji kpokọta ihe ndị dị na oyi akwa interposer, ngwugwu 3D IC na-ejikọta ọtụtụ akwa nke silicon wafers na-eji TSVs.

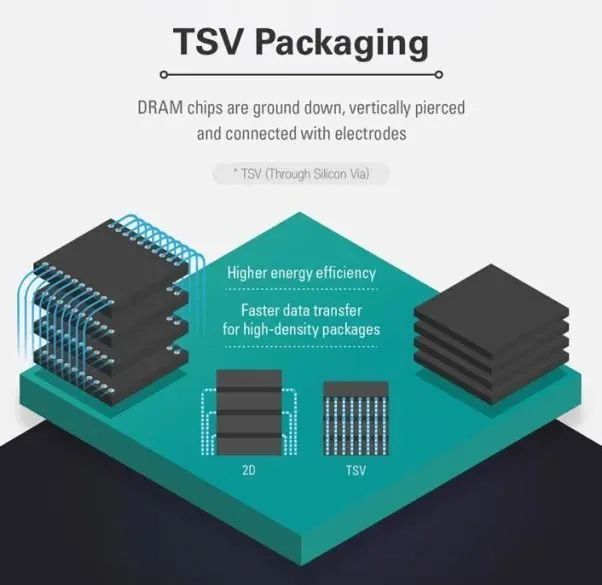

Teknụzụ TSV bụ isi teknụzụ na-enye aka na ngwugwu 2.5D na 3D IC, ụlọ ọrụ semiconductor na-eji teknụzụ HBM mepụta ibe DRAM na ngwugwu 3D IC.

Nleba anya n'ofe akụkụ nke ngwugwu 3D na-egosi na a na-enweta njikọ kwụ ọtọ n'etiti ibe silicon site na TSV ọla kọpa dara.

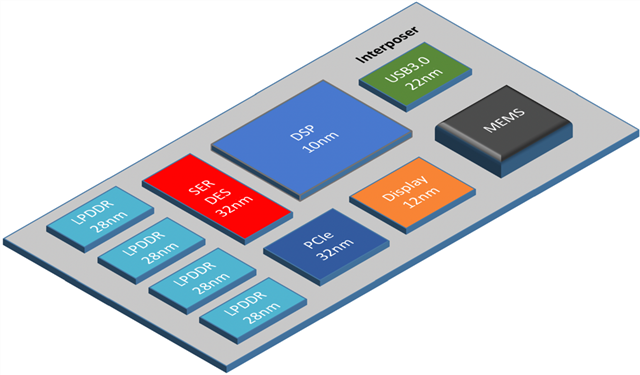

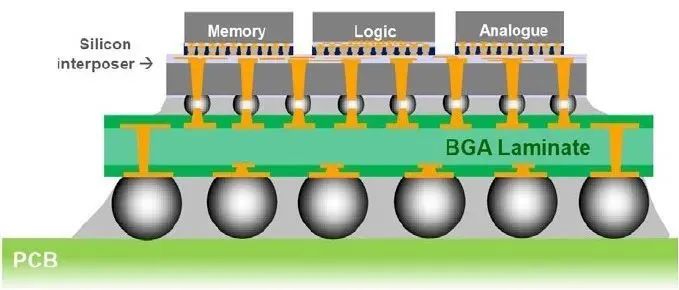

Chiplet

Chiplets bụ ụdị ọzọ nke nkwakọ ngwaahịa 3D IC nke na-enyere njikọ dị iche iche nke CMOS na ihe ndị na-abụghị CMOS aka.N'ikwu ya n'ụzọ ọzọ, ha bụ obere SoCs, nke a na-akpọkwa chiplets, kama ịbụ nnukwu SoC na ngwugwu.

Na-akụda nnukwu SoC n'ime obere, obere ibe na-enye mkpụrụ dị elu yana ọnụ ala karịa otu anwụ anwụ.chiplets na-ekwe ka ndị na-emepụta ihe na-eji ohere dị iche iche nke IP eme ihe n'ebughị ụzọ tụlee usoro ọnụ ụzọ ha ga-eji na nkà na ụzụ ha ga-eji rụọ ya.Ha nwere ike iji ihe dị iche iche, gụnyere silicon, iko na laminates rụpụta mgbawa.

Sistemụ dabere na Chiplet bụ nke nwere ọtụtụ Chiplets na oyi akwa etiti

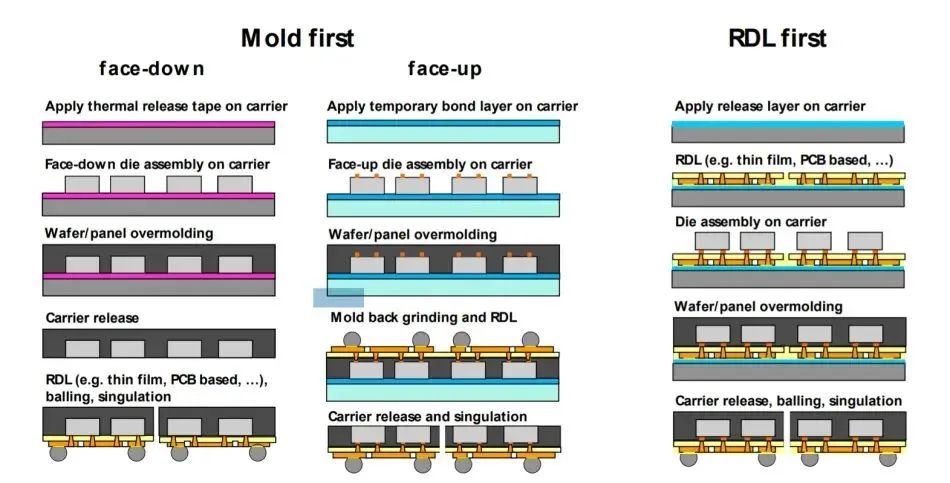

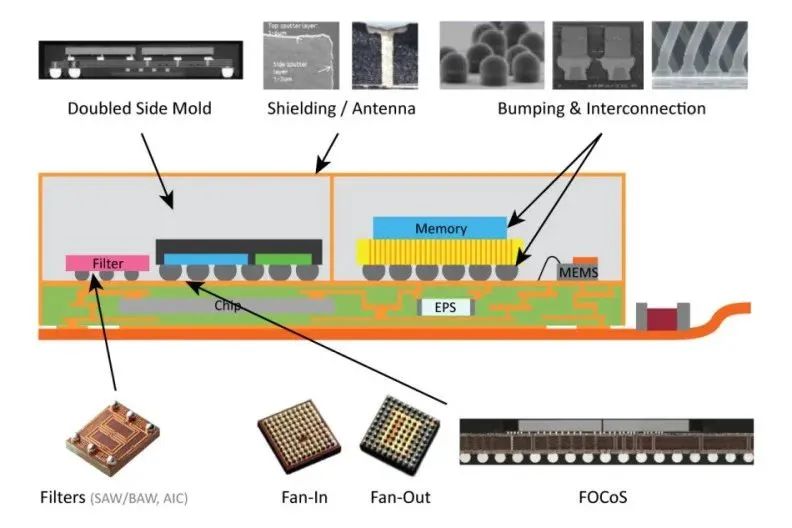

Ihe ngwungwu Fans

N'ime ngwugwu Fan Out, a na-ewepụ "njikọ" ahụ n'elu mgbawa iji nyekwuo I/O mpụga.Ọ na-eji ihe na-akpụzi epoxy (EMC) nke etinyere n'ụzọ zuru ezu na anwụ anwụ, na-ewepụ mkpa maka usoro dị ka mgbaka wafer, fluxing, flip-chip mounting, ihicha, ịgbasa ala na ọgwụgwọ.Ya mere, ọ dịghị oyi akwa intermediary achọrọ ma, na-eme ka njikọta dị iche iche dị mfe karị.

Teknụzụ fan-out na-enye ngwugwu pere mpe nwere ọtụtụ I / O karịa ụdị ngwugwu ndị ọzọ, na 2016 ọ bụ kpakpando teknụzụ mgbe Apple nwere ike iji teknụzụ nkwakọ ngwaahịa TSMC iji tinye ngwa ngwa 16nm ya na DRAM mkpanaka ya n'otu ngwugwu maka iPhone. 7.

Nkwakọ ngwaahịa fan-out

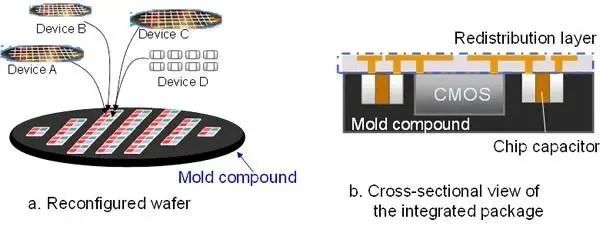

Nkwakọ ngwaahịa ọkwa Wafer (FOWLP)

Teknụzụ FOWLP bụ nkwalite na nkwakọ ngwaahịa ọkwa wafer (WLP) nke na-enye ọtụtụ njikọ mpụga maka ibe silicon.Ọ na-agụnye itinye mgbawa ahụ n'ime ihe na-akpụzi epoxy wee wuo oyi akwa redistribution redistribution (RDL) dị elu n'elu wafer na itinye bọọlụ na-ere ere iji mepụta wafer arụgharịrị.

FOWLP na-enye ọnụ ọgụgụ buru ibu nke njikọ n'etiti ngwugwu na bọọdụ ngwa, na n'ihi na mkpụrụ osisi buru ibu karịa anwụ, ụda anwụ na-adị jụụ karị.

Ọmụmaatụ nke ngwungwu FOWLP

Ngwakọta dị iche iche

Ngwakọta nke ihe dị iche iche emepụtara iche iche n'ime mgbakọ dị elu nwere ike ịkwalite ọrụ ma melite njirimara ọrụ, ya mere ndị na-emepụta ihe na-emepụta semiconductor na-enwe ike ijikọta ihe ndị na-arụ ọrụ na usoro dị iche iche na-abanye n'ime otu mgbakọ.

Njikọ dị iche iche dị ka sistemụ-in-ngwugwu (SiP), mana kama ijikọta ọtụtụ anwụ efu na otu mkpụrụ, ọ na-ejikọta ọtụtụ IP n'ụdị Chiplets na otu mkpụrụ.Echiche bụ isi nke njikọta dị iche iche bụ ijikọta ọtụtụ ihe nwere ọrụ dị iche iche n'otu ngwugwu.

Ụfọdụ teknuzu ụlọ ngọngọ na iche iche mwekota

HBM

HBM bụ teknụzụ nchekwa nchịkọta ahaziri ahazi nke na-enye ọwa bandwidth dị elu maka data n'ime nchịkọta yana n'etiti ebe nchekwa yana ihe ezi uche dị na ya.Ngwunye HBM na-akwakọba ebe nchekwa na-anwụ wee jikọta ha ọnụ site na TSV iji mepụta ọtụtụ I/O na bandwit.

HBM bụ ọkọlọtọ JEDEC nke na-ejikọta ọtụtụ akụkụ nke DRAM n'ime ngwugwu, yana ngwa nhazi, GPUs na SoCs.A na-emejuputa HBM dịka ngwugwu 2.5D maka sava dị elu na ibe netwọk.Mwepụta HBM2 na-eleba anya ugbu a ikike na oke ọnụego elekere nke ntọhapụ HBM mbụ.

HBM ngwugwu

Okirikiri etiti

Okpokoro interposer bụ ụzọ ebe a na-esi na ya na-ebufe akara ọkụ eletrik site na multi-chip bare die ma ọ bụ bọọdụ dị na ngwugwu.Ọ bụ njikọ eletrik n'etiti oghere ma ọ bụ njikọ, na-ekwe ka ịgbasa mgbaàmà ndị ahụ pụọ ma jikọọ na oghere ndị ọzọ na osisi.

The interposer oyi akwa nwere ike mere nke silicon na organic ihe na-eme dị ka a àkwà mmiri n'etiti multi-anwụ anwụ na osisi.Silicon interposer Layers bụ teknụzụ egosipụtara na njupụta I / O dị elu yana ikike imepụta TSV ma rụọ ọrụ dị mkpa na nkwakọ ngwaahịa 2.5D na 3D IC.

Mmejuputa a na-ahụkarị nke oyi akwa etiti kewara sistemu

oyi akwa nkesa

Okpokoro nkesagharị nwere njikọ ọla kọpa ma ọ bụ nhazi nke na-eme ka njikọ eletrik dị n'etiti akụkụ dị iche iche nke ngwugwu ahụ.Ọ bụ akwa akwa ọla ma ọ bụ polymeric dielectric nke enwere ike idokọ ya na ngwugwu na-anwụ anwụ, si otú a na-ebelata ohere I/O nke nnukwu chipsets.Ntugharị redistribution aghọwo akụkụ dị mkpa nke ngwọta ngwugwu 2.5D na 3D, na-ekwe ka ibe dị na ha na-ekwurịta okwu na ibe ha site na iji intermediary layers.

Ngwakọta agbakwunyere na-eji akwa nkesagharị

TSV

TSV bụ teknụzụ mmejuputa isi maka 2.5D na ngwọta nkwakọ ngwaahịa 3D yana wafer jupụtara na ọla kọpa nke na-enye njikọ kwụ ọtọ site na silicon wafer anwụ.Ọ na-agba ọsọ site na ọnwụ dum iji nye njikọ eletriki, na-eme ụzọ kacha nso site n'otu akụkụ nke ọnwụ gaa na nke ọzọ.

A na-edobe oghere ma ọ bụ vias na omimi ụfọdụ site n'akụkụ ihu nke wafer, nke a na-ekpuchi ma jupụta site na itinye ihe na-eduzi (na-emekarị ọla kọpa).Ozugbo a na-emepụta mgbawa ahụ, a na-esi n'azụ azụ nke wafer ahụ kpughee vias na ígwè a na-etinye n'akụkụ azụ nke wafer iji mezue njikọ TSV.

Oge nzipu: Jul-07-2023