Ịtụkwasị na n'ọkwa nkeakwụkwọ ntuziakasolderebipụtaer

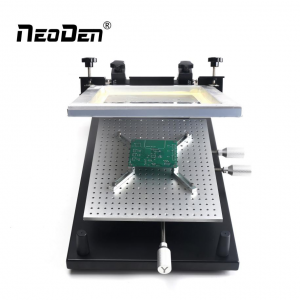

N'ahịrị mmepụta SMT, mbipụta bụ ịkwanye mado na-ere ahịa na paịlị kwekọrọ na PCB iji kwado maka patch ọzọ.Ihe nbipute na-eji aka na-arụ ọrụ na-ezo aka na usoro iji aka na-ebi akwụkwọ tapawa solder site na iji igwe eji ebi akwụkwọ.

Usoro ọrụ nke ngwa nbipute akwụkwọ ntuziaka na-agụnye itinye efere efere, n'ọnọdu, ibipụta, efere efere naihicha ígwè ntupu.

- Ntupu ígwè edoziri

Jiri ngwaọrụ edozi iji dozie nchara nchara na igwe obibi akwụkwọ.Mgbe edozichara, hụ na nchara nchara na PCB nọ na kọntaktị dị larịị.Enweghị kọntaktị na-adịghị mma ma ọ bụ otu akụkụ nwere ike ime, ma ọ bụghị ya, ọ dị mfe ime ka ọdịda nke ebe obibi akwụkwọ na-edozi ihe na-edozi, na-emetụta àgwà obibi akwụkwọ na ndụ ọrụ nke nchara ígwè. - Ebe PCB dị

Akwụkwọ ntuziaka, PCB n'ozuzu na-anakwere n'ọkwa n'akụkụ efere efere, ya bụ, n'ọnọdu dabere na ọnọdụ nke oghere oghere na osisi.Mgbe etinyere ya, ntupu nke nchara nchara ga-adakọrịrị nke ọma na paịlị kwekọrọ na PCB.Iji nwee ọdịdị nkwonkwo dị mma, a na-achọkarị ka pasta ihe na-esi na ya na ogo dislocation na-erughị 10%.

Ebipụtara nzọụkwụ 4 aka

- Usoro obibi akwụkwọ bụ isi nwere usoro anọ ndị a.

(1) okpomọkụ na ịgwakọta ezigbo solder tapawa larịị na glued na ígwè net, solder mado anaghị ewere nke ukwuu, na-ebi akwụkwọ na mgbakwunye. - Ekwesịrị idowe PCB nke a ga-ebipụta n'ụzọ ziri ezi na tebụl obibi akwụkwọ, tinye nchara nchara, wee lelee ma ntupu ahụ dabara nke ọma na mpe mpe akwa PCB.

- Jiri ihe nchacha kpochaa tapawa ihe na-ere ihe iji mee ka tapawa ihe na-ere ihe na mpịakọta nchara nchara wee bipụta site n'elu ruo na ala n'akụkụ ntụziaka nke PCB.

- Wepu PCB e biri ebi na tebụl obibi.Lelee ma enwere ntapu, gbamgbam karịa, obere tin, ọbụlagodi ihe nbipụta.Ọ bụrụ na erughị eru, jiri bọọdụ a na-asa ákwà wepụ ya mado ma bipụtaghachi ya ma bọọdụ akpọnwụwo

Anyị na-enyekwaọkara akpaaka solder ngwa nbipute, ọ bụrụ na ịchọrọ, nweere onwe gị ịkpọtụrụ anyị.

Oge nzipu: Jan-21-2021